- Indicated Resources (open pit and underground*) of 572 kt at 0.61% Ni (7.7M lbs Ni) – 44% increase in Indicated tonnes and 10% increase in nickel pounds.

- Inferred Resources (open pit and underground*) of 125 kt at 0.54% Ni (1.5M lbs Ni) – 693% increase in Inferred tonnes and 419% increase in nickel pounds.

- 84% of the nickel pounds and 82% of the tonnes in Alexo South Deposit Mineral Resource Estimate are in the Indicated category with drilling planned to update to Measured.

- With only 18% of the Alexo South Deposit tonnes in the Inferred category there is excellent exploration upside to expand and upgrade resources through additional drilling.

- Alexo South Deposit, one of 4 deposits on the Alexo-Dundonald Property, is open along strike and at depth, with the new geological model and interpretation providing ample targets for next-stage drilling.

- Updated Mineral Resource Estimate work continuing on the remaining 3 deposits of the Alexo-Dundonald Nickel Project.

*C$52.5/t NSR open pit and C$96.0/t NSR underground cut-offs applied in current 2024 mineral resource estimate whereas a C$30.0/t NSR open pit and C$90.0/t NSR underground cut-offs were applied in the 2020 mineral resource estimate.

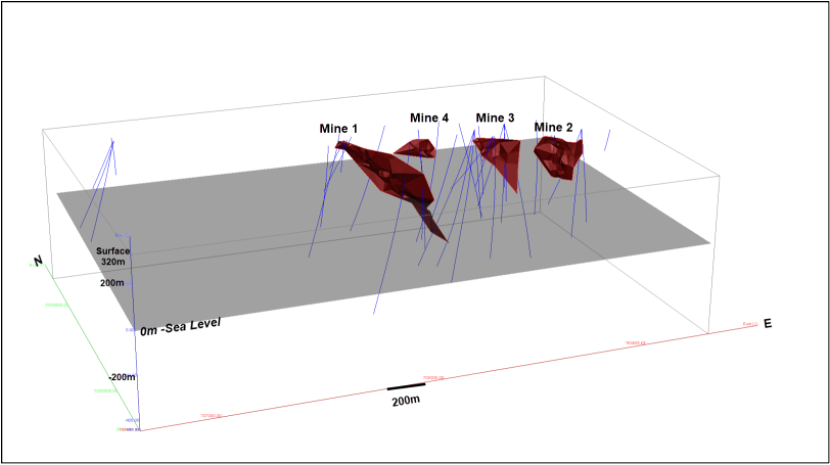

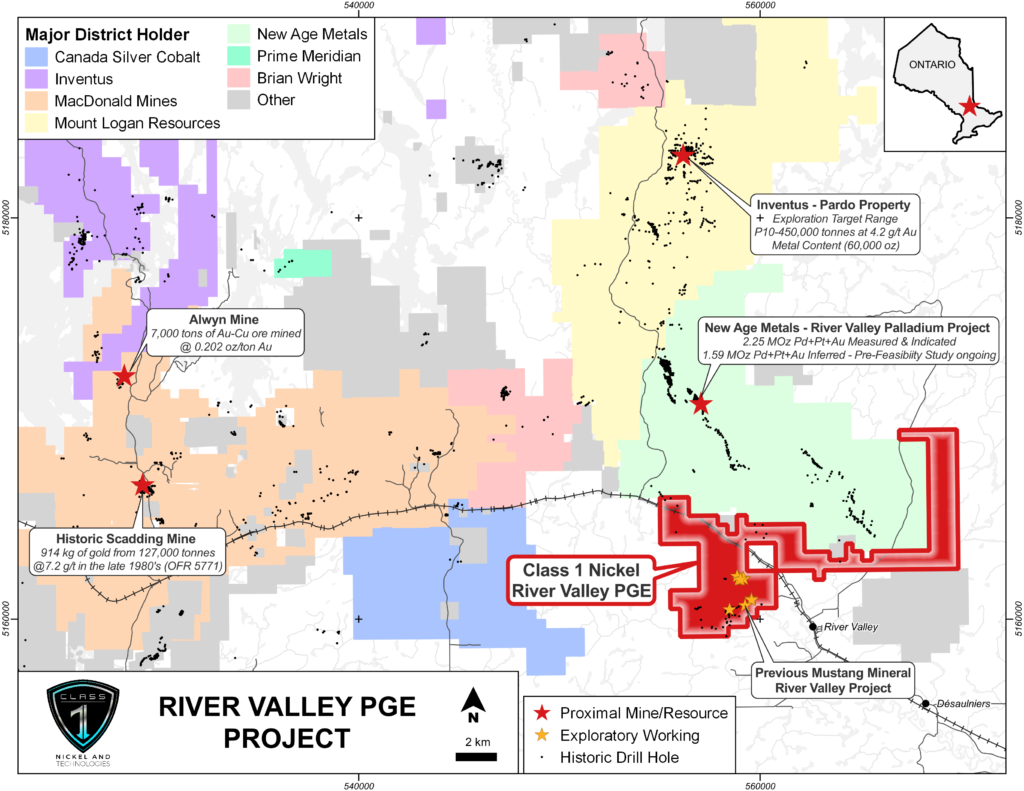

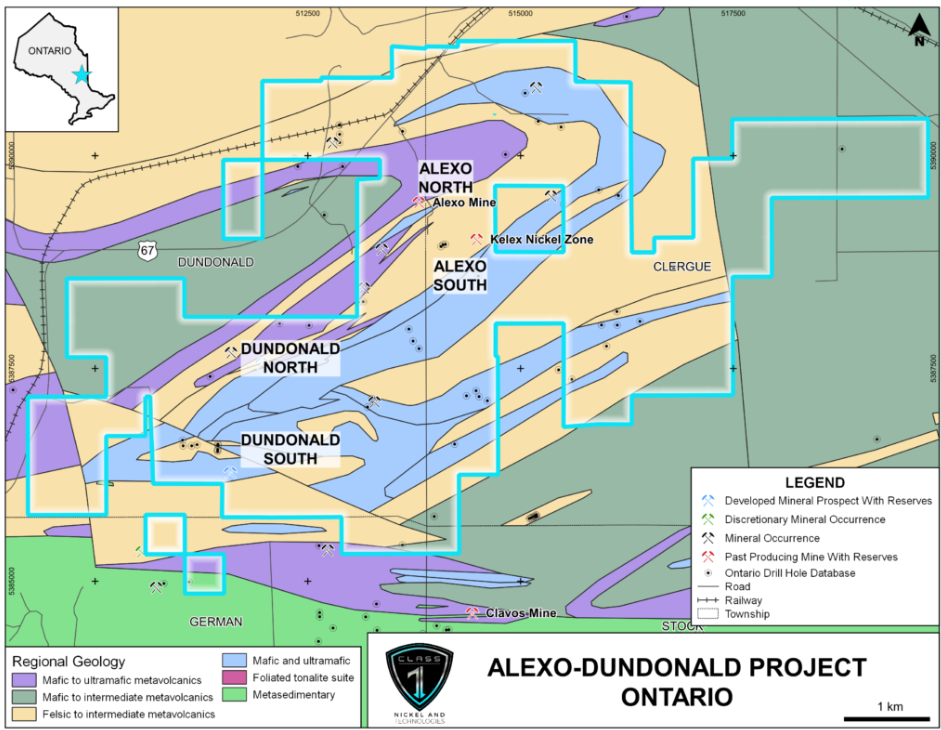

TORONTO, April 24, 2024 (GLOBE NEWSWIRE) — Class 1 Nickel and Technologies Ltd. (CSE: NICO | OTCQB: NICLF) (“Class 1 Nickel” or the “Company”) is pleased to announce an updated mineral resource estimate (“MRE”) for the Alexo South Nickel Deposit (“A-S Deposit”) (Table 1). The A-S Deposit, located about 45 km northeast of the City of Timmins, Ontario, is one of 4 high-grade nickel deposits within the extensive Alexo-Dundonald Nickel Project (the “Project”) (Figure 1), which covers approximately 1,895 hectares (18.95 km2). Updates to the other 3 nickel mineral resources contained within the Project will be completed over the coming months.

Table 1. Mineral Resource Statement for the 2024 Alexo South Indicated and Inferred Resources estimate.

| Alexo South Resource Category | Tonnage (t) | Grade | Contained Metal | |||||||

| Ni (%) | Cu (%) | Co (%) | NiEq (%) | NSR (C$/t) | Ni (klbs) | Cu (klbs) | Co (klbs) | |||

| Open Pit ($52.5/t NSR COG) | ||||||||||

| Indicated | 275,047 | 0.58 | 0.02 | 0.02 | 0.62 | 123.38 | 3,493 | 133 | 133 | |

| Inferred | 0 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0 | 0 | 0 | |

| Total Pit Constrained | 275,047 | 0.58 | 0.02 | 0.02 | 0.617 | 123.38 | 3,493 | 133 | 133 | |

| Underground (C$96.0/t NSR COG) | ||||||||||

| Indicated | 296,799 | 0.65 | 0.03 | 0.02 | 0.69 | 138.66 | 4,240 | 190 | 157 | |

| Inferred | 125,226 | 0.54 | 0.03 | 0.02 | 0.58 | 116.11 | 1,502 | 75 | 52 | |

| Total Out-of-Pit | 422,025 | 0.62 | 0.03 | 0.02 | 0.66 | 131.97 | 5,742 | 264 | 209 | |

| Total Open Pit and Underground Resources | ||||||||||

| Indicated | 571,846 | 0.61 | 0.03 | 0.02 | 0.66 | 131.31 | 7,733 | 323 | 290 | |

| Inferred | 125,226 | 0.54 | 0.03 | 0.02 | 0.58 | 116.11 | 1,502 | 75 | 52 | |

| Total Resources | 697,072 | 0.60 | 0.03 | 0.02 | 0.64 | 128.58 | 9,235 | 398 | 343 | |

Notes to Table 1:

(1) The independent Qualified Person for the MRE, as defined by NI 43-101, is Mr. Simon Mortimer (FAIG #4083) of Atticus Geoscience Consulting S.A.C., working with Caracle Creek International Consulting Inc. The effective date of the MRE is 19 April 2024.

(2) Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability.

(3) The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, title, taxation, socio-political, marketing, or other relevant issues.

(4) The Inferred Mineral Resource in this estimate has a lower level of confidence than that applied to an Indicated Mineral Resource and must not be converted to a Mineral Reserve. It is reasonably expected that the majority of the Inferred Mineral Resource could be upgraded to an Indicated Mineral Resource with continued exploration.

(5) The Mineral Resources were estimated following the 2019 CIM Estimation of Mineral Resources & Mineral Reserves Best Practice Guidelines prepared by the CIM Mineral Resource & Mineral Reserve Committee and the 2014 CIM Definition Standards for Mineral Resources & Mineral Reserves prepared by the CIM Standing Committee on Reserve Definitions.

(6) Geological and block models for the MRE used core assays (2,254 samples from 2021 drilling and 178 samples from 2024 in-fill core sampling) and data and information from 181 surface diamond drill holes (29 from Class 1 Nickel and 152 historical). The drill hole database was validated prior to resource estimation and QA/QC checks were made using industry-standard control charts for blanks, core duplicates and commercial certified reference material inserted into assay batches by Class 1 Nickel.

(7) The block model was prepared using Micromine 2020. A 6 m x 6 m x 6 m block model was created, with sub blocks to 0.5 m x 0.5 m x 0.5 m. Drill composites of 1.0 m intervals were generated within the estimation domains, and subsequent grade estimation was carried out for Ni, Cu and Co using Ordinary Kriging interpolation method.

(8) Grade estimation was validated by comparison of input and output statistics (Nearest Neighbour and Inverse Interpolation methods), swath plot analysis, and by visual inspection of the assay data, block model, and grade shells in cross-sections.

(9) As a reference, the average estimated density value (specific gravity) within the mineralised domain is 2.89 g/cm3 (t/m3).

(10) Estimates have been rounded to 3 significant figures for Indicated resources and 2 significant figures for Inferred resources.

(11) The historical open pit mined areas were removed from the MRE and the MRE considers a geological dilution of 5% and a mining recovery of 95%.

(12) US$ metal prices of $8.00/lb Ni, $3.25/lb Cu, $13.00/lb Co were used in the NSR calculation with respective process recoveries of 85%, 70%, and 80%; gold, platinum and palladium are not considered in the current NSR calculation.

(13) Pit constrained Mineral Resource NSR cut-off considers processing, and G&A costs, applying a factor of 5% for mining dilution, that respectively combine for a total of (($45.00 + $5.00) * (1 + 5%)) = C$52.5/tonne processed.

(14) Out-of-pit Mineral Resource (underground) NSR cut-off considers ore mining, processing, and G&A costs that respectively combine for a total of ($46.00 + $45.00 + $5.00) = C$96.0/tonne processed.

(15) The out-of-pit Mineral Resource grade blocks were quantified above the $96.0/t cut-off, below the constraining pit shell and within the constraining mineralized wireframes. Additionally, only groups of blocks that exhibited continuity and reasonable potential stope geometry were included. All orphaned blocks and narrow strings of blocks were excluded. The long-hole stoping with backfill mining method was assumed for the out-of-pit (underground) MRE calculation.

(16) The NSR calculation is as follows: NSR C$/t = ((Ni% x 199.89) + (Cu% x 66.87) +(Co% x 305.71)) x 95%.

(17) The NiEq% calculation is as follows: NiEq% = (Ni% x 1) + (Cu% x 0.33) + (Co% x 1.53).

David Fitch, CEO of Class 1 Nickel, commented: “After several months of detailed data compilation, geological modelling and interpretation, we finally have what we consider to be the first comprehensive mineral deposit model for Alexo South. This work allows to now target for future drilling programs using the most optimal information available with the ultimate goal of expanding mineral resources and moving into economic studies such as a Preliminary Economic Assessment which is planned for 2024.”

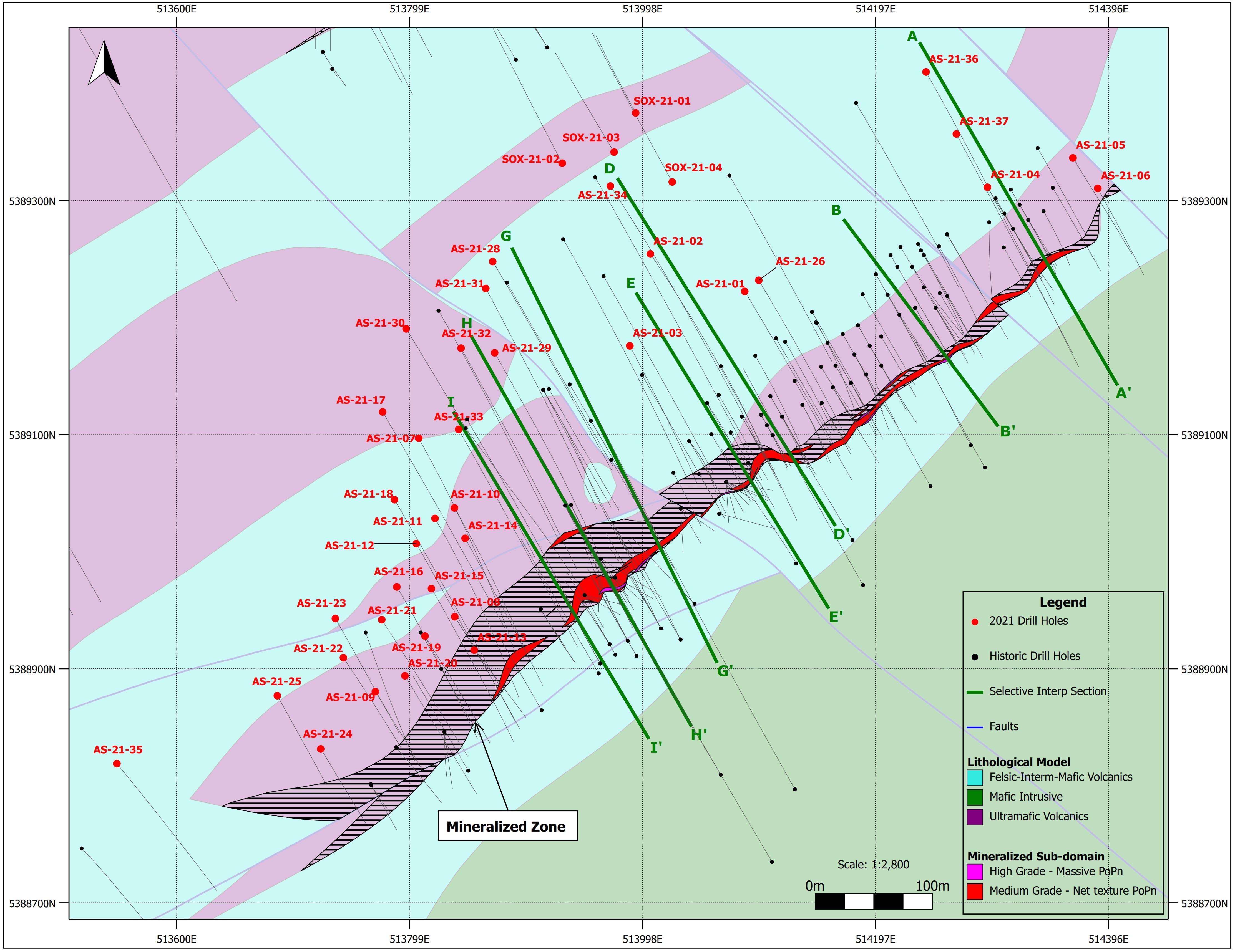

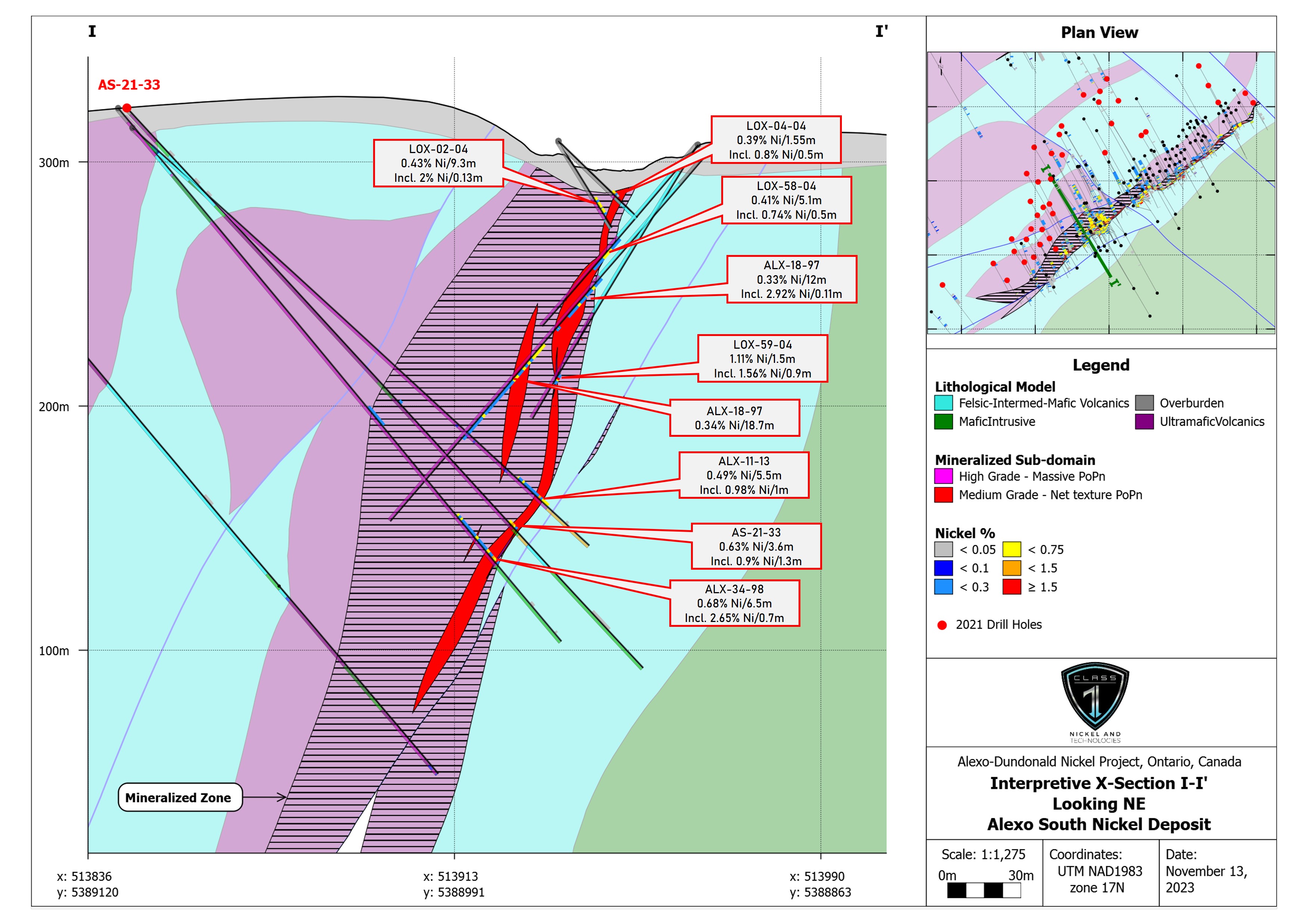

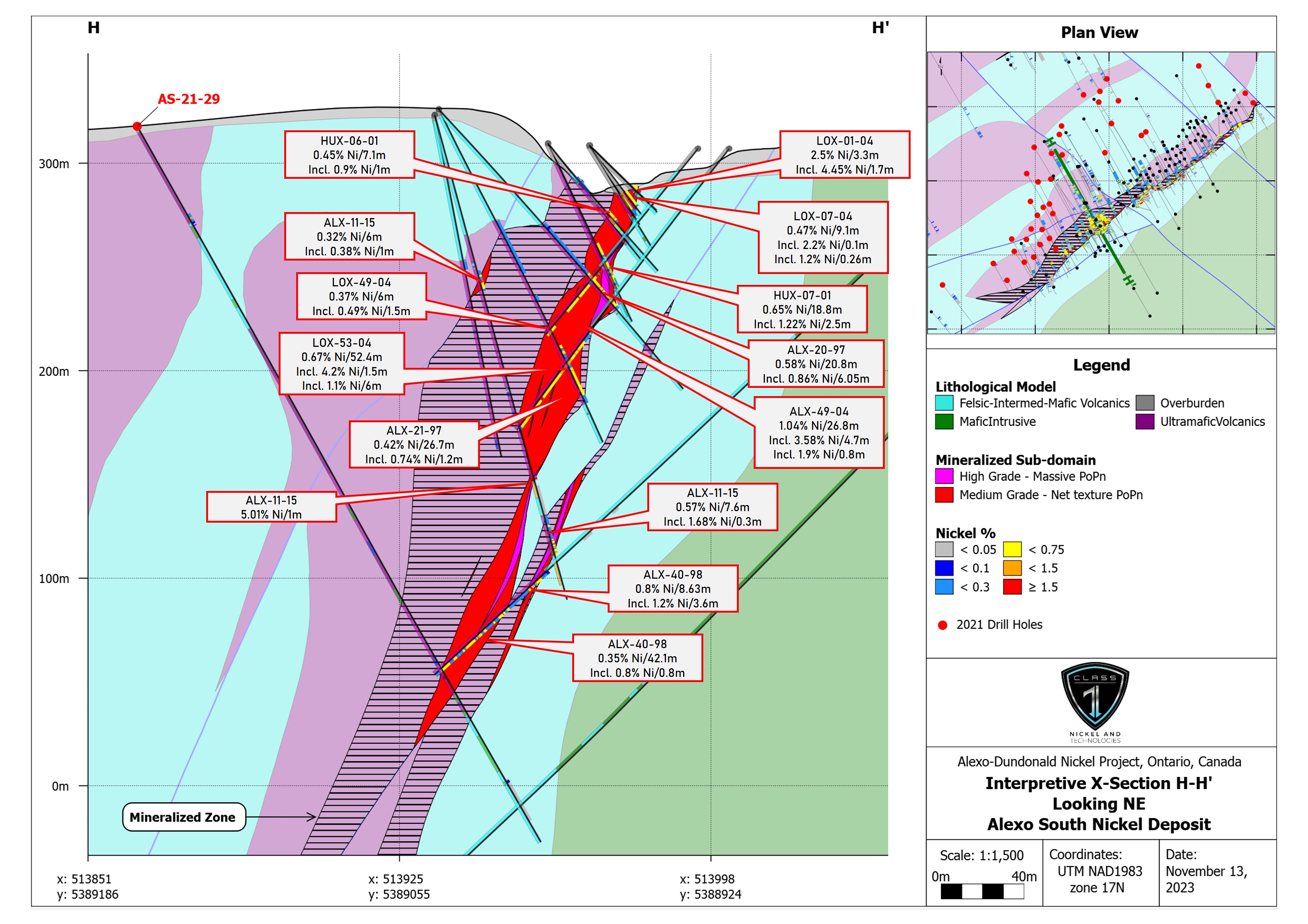

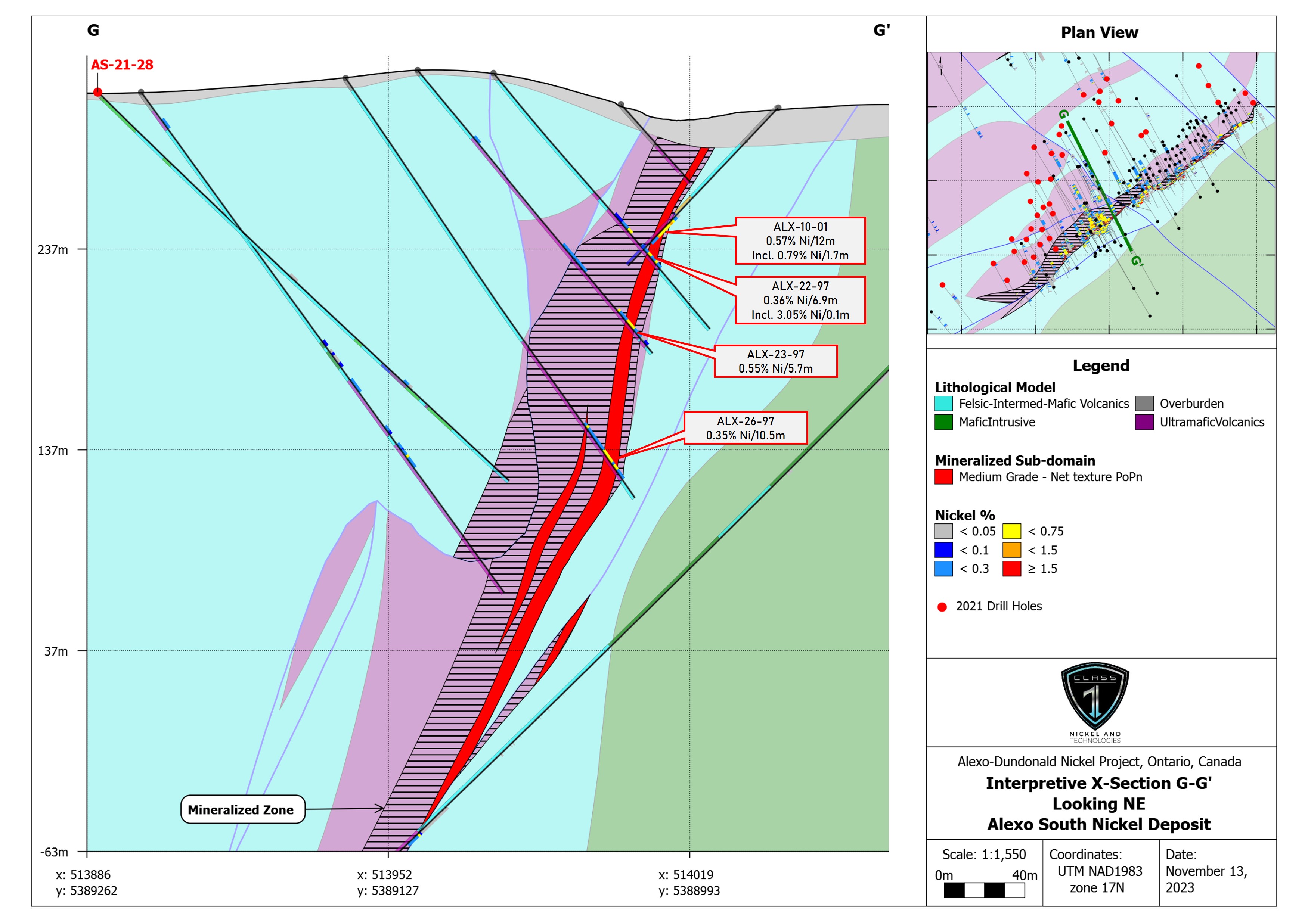

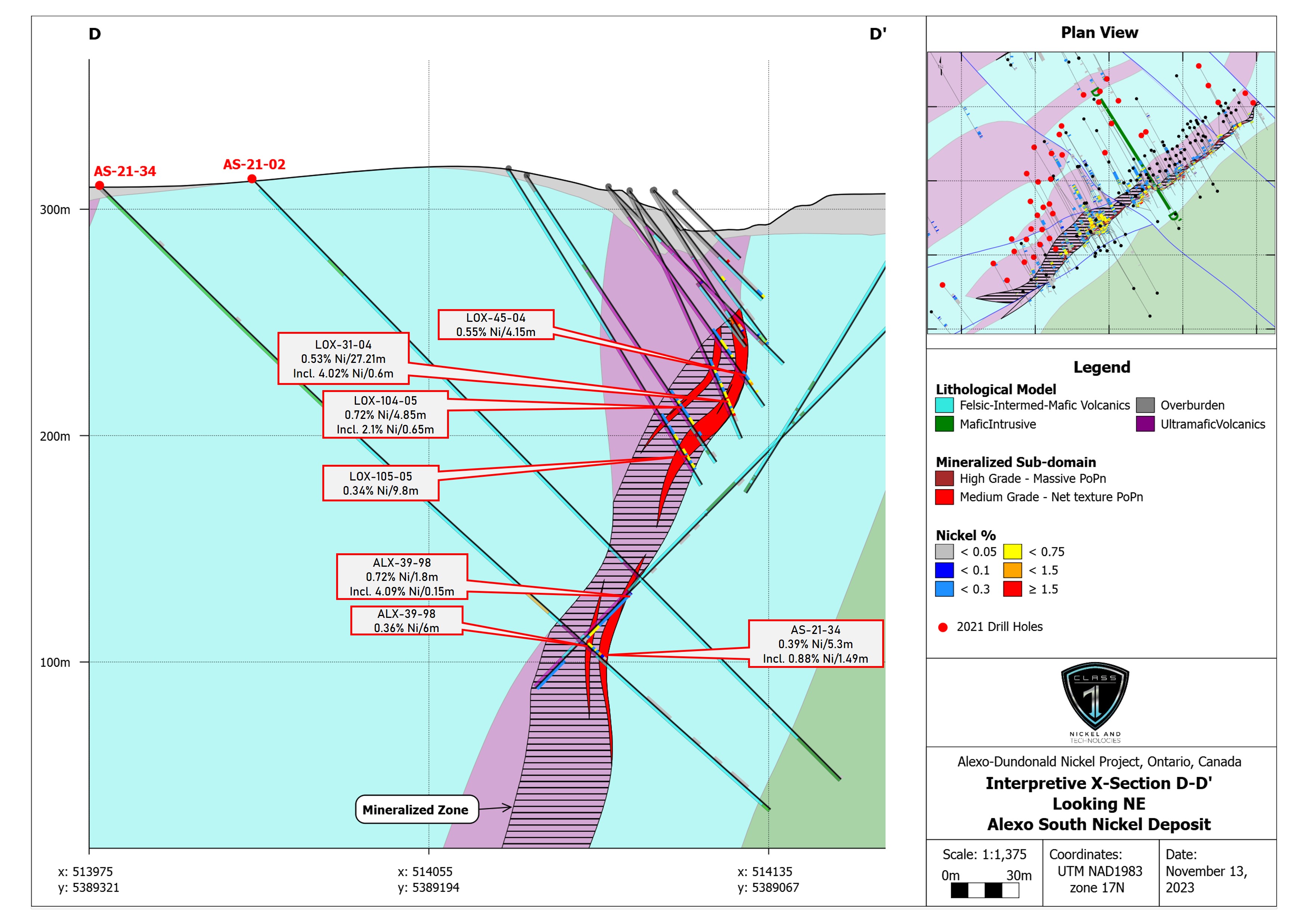

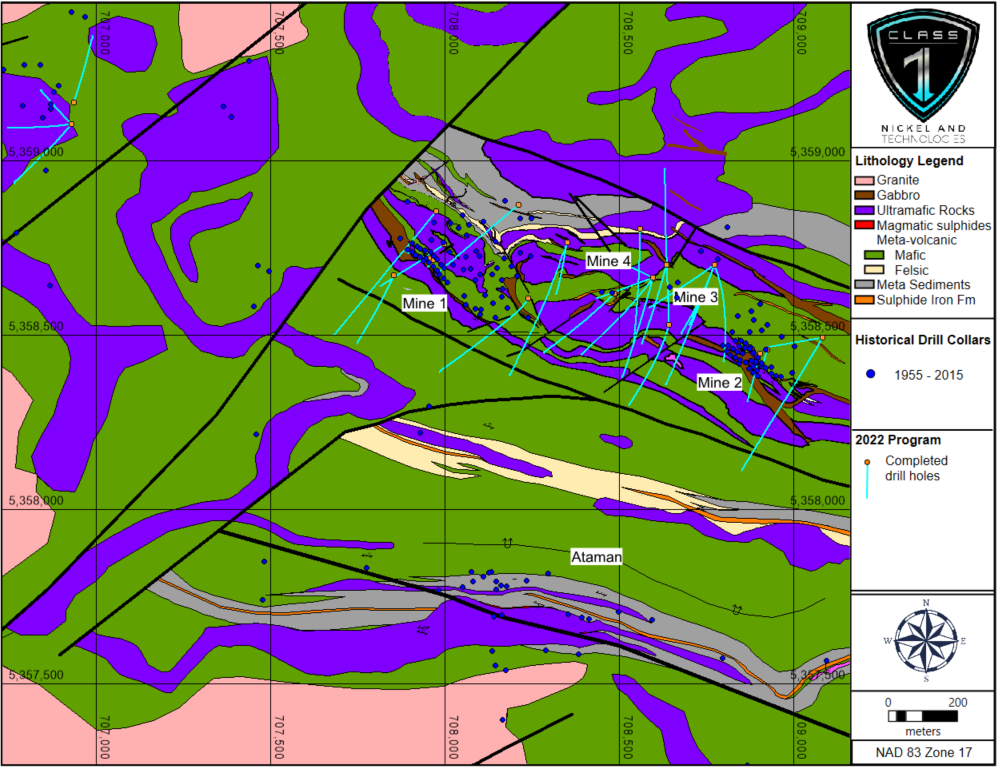

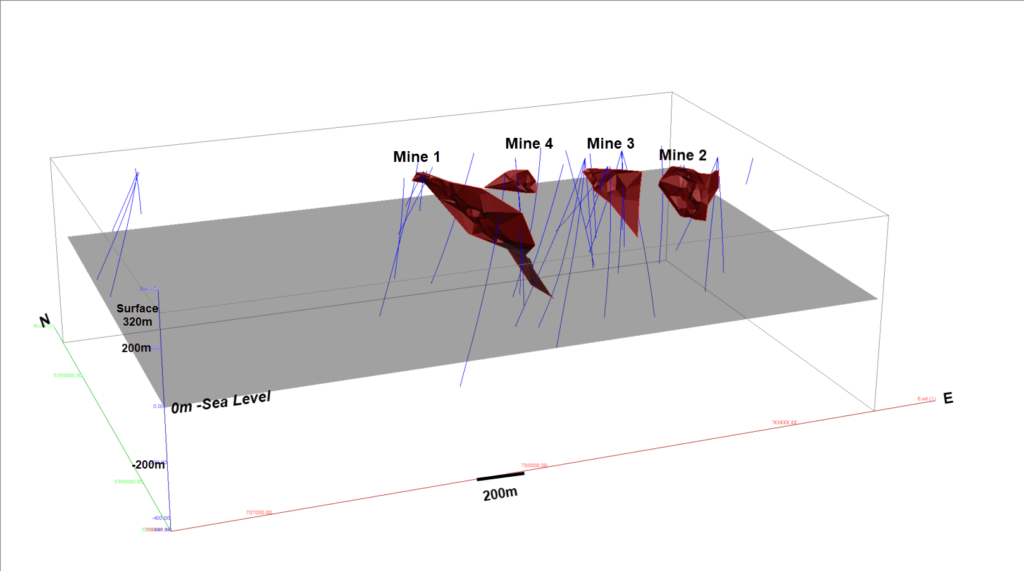

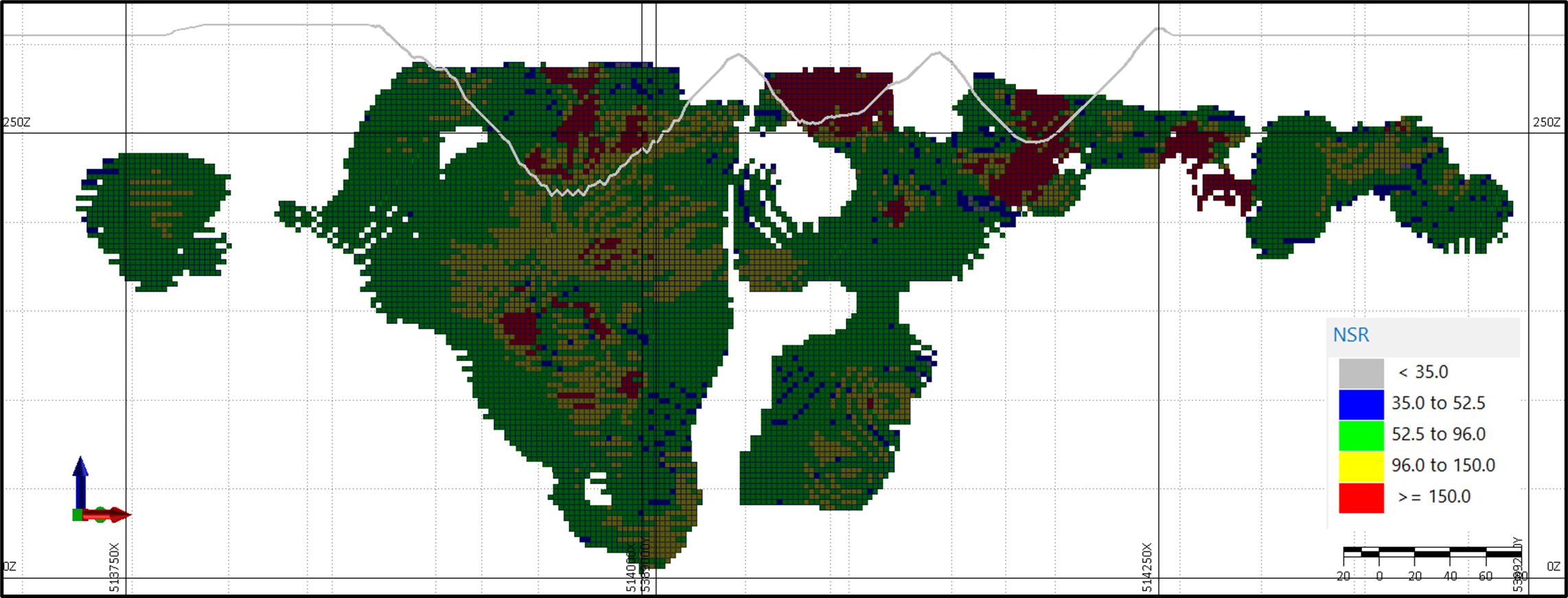

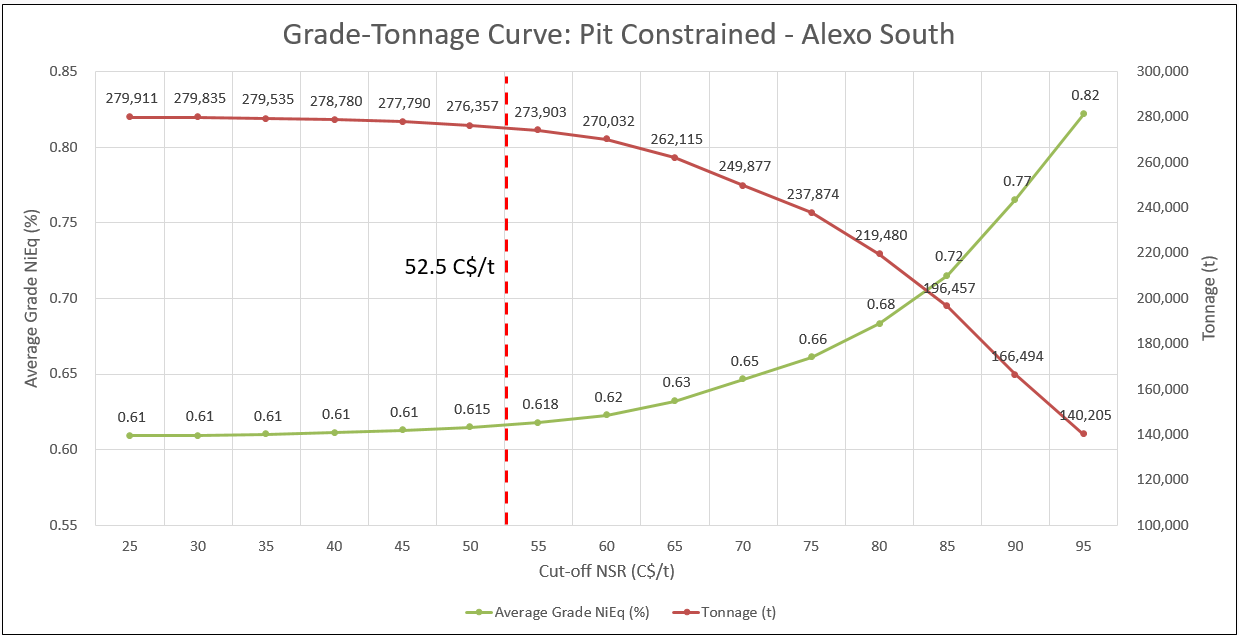

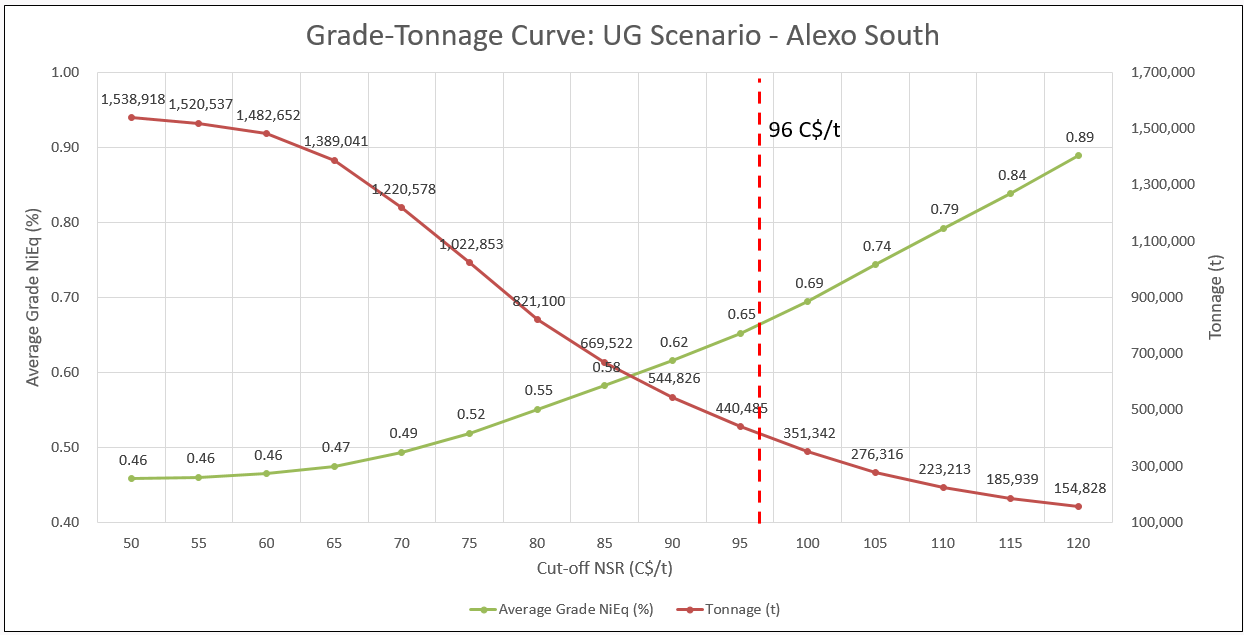

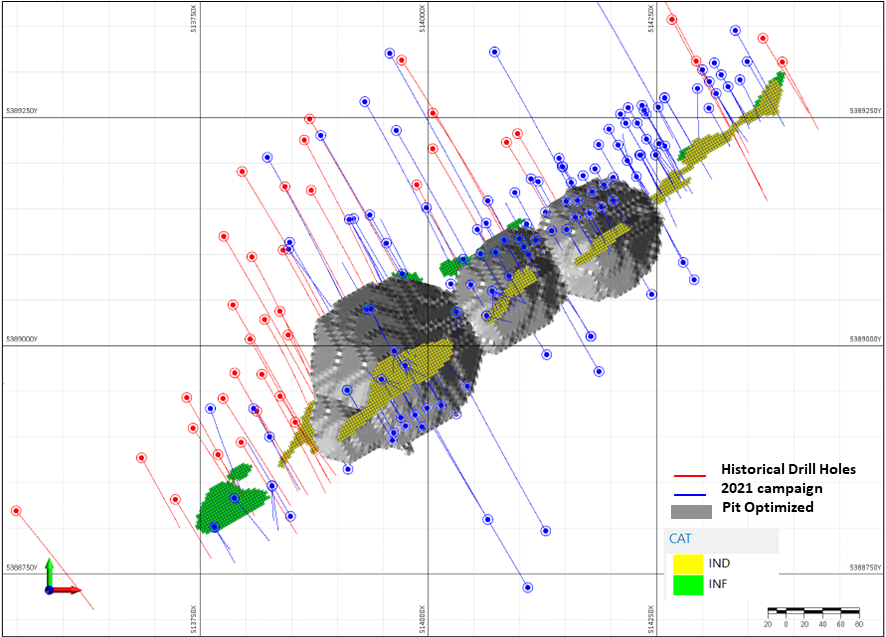

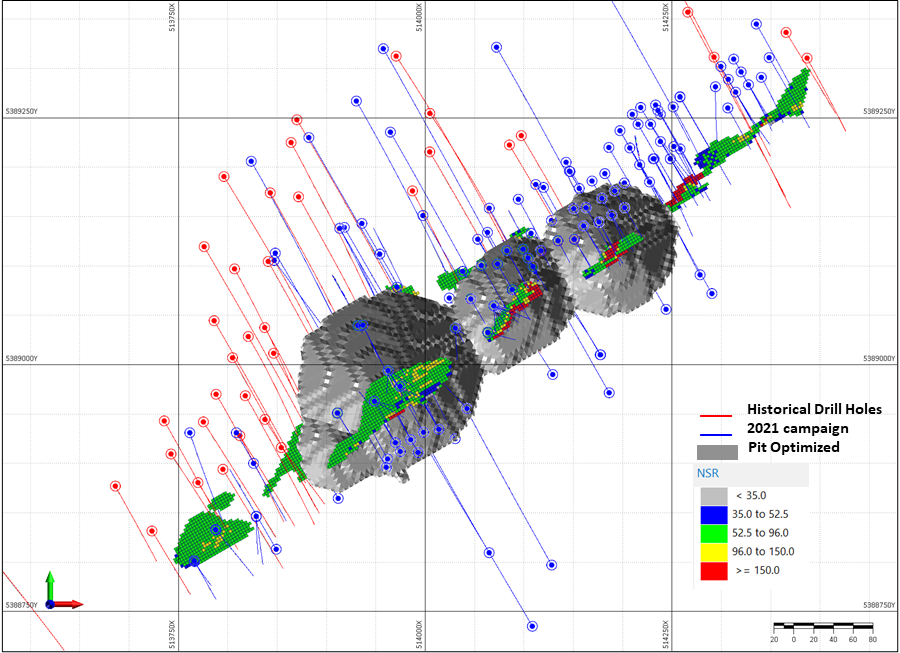

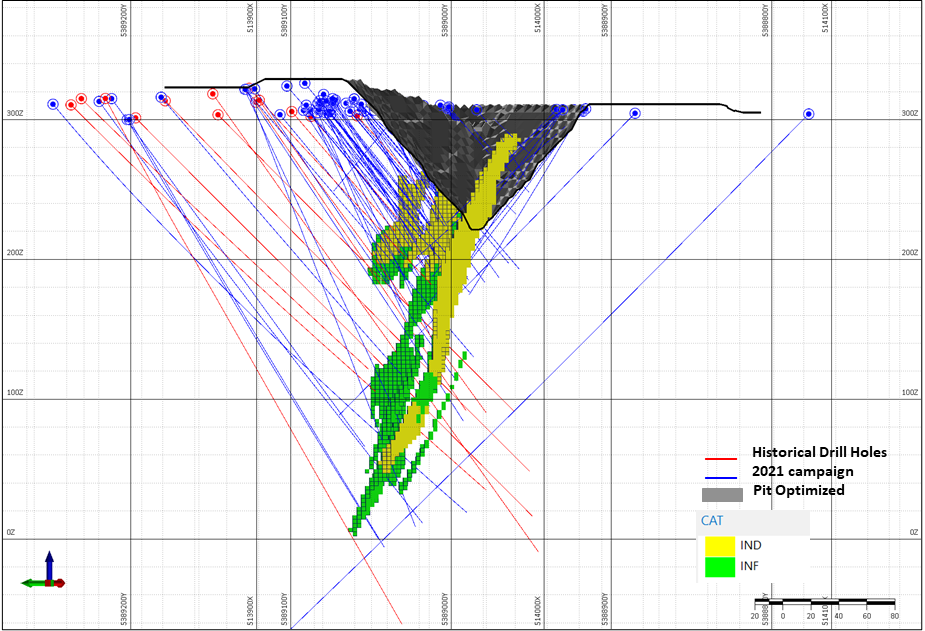

Class 1 Nickel completed diamond drilling on the Alexo-Dundonald Nickel Project (“A-D Project”) in 2021 with 9,222 m in 37 holes (869 samples) completed at Alexo South. The updated mineral resource estimate combines the new drill hole data with historical drilling (24,237 m in 184 holes) completed on the A-S Deposit by previous operators including the most recent drilling by Canadian Arrow (10,128 m in 105 drill holes, 2004 to 2005) and First Nickel (985 m in 10 drill holes, 2004). A cross-section view of the current MRE and optimized pit shell is provided in Figure 2. Grade-Tonnage Curves for the open pit and out-of-pit resources are provided in Figure 3 and Figure 4, respectively. Various views of the Alexo South MRE are also shown in Figures 5, 6 and 7.

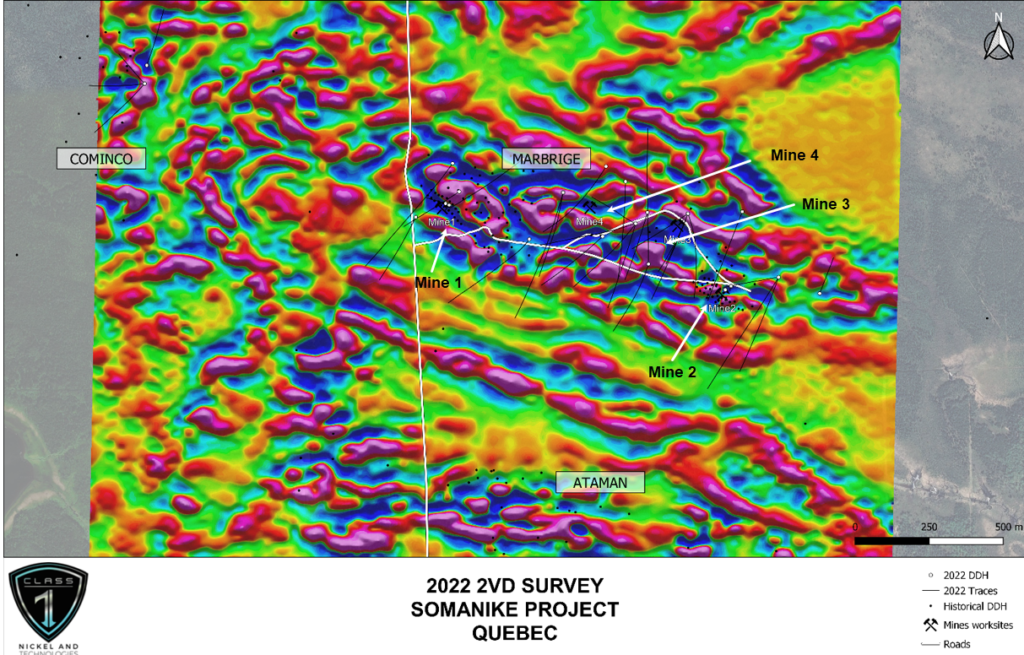

Figure 1. Location of the Alexo-Dundonald Nickel Project in the Timmins Mining Camp, Ontario and the location of the 4 nickel sulphide deposits.

The updated MRE was completed by Caracle Creek Chile SpA (“Caracle”) and their strategic partner Atticus Geoscience Consulting Ltd. (“Atticus”) (together the “Consultants”) and this resource replaces the 2020 mineral resource estimate completed by P&E Mining Consultants Inc. (Stone et al., 2020) which is filed on SEDAR+. The current MRE has been completed in accordance with National Instrument 43-10 (“NI-43-101”) and a technical report in support the MRE will be filed on SEDAR+ within 45 days from the date of this news release.

As stated in the Company’s recent news release dated 18 April 2024, the primary objectives of the Company are to expand known mineralization and resources at its 4 existing magmatic nickel sulphide deposits within the Alexo-Dundonald Nickel Project. Furthermore, the Company will be launching an exploration program to examine the as yet underexplored areas of the Project including the numerous nickel sulphide occurrences that exist outside of the known deposit areas. Much of this exploration will be guided by recently completed airborne geophysics and historical drilling, with new ground geophysics and remote sensing surveys being planned.

Figure 2. Cross-sectional view (looking northwest) through the Alexo South Deposit showing the C$/t NSR value distribution in each block and the trace of the optimized open pit shell.

Figure 3. Grade-tonnage curve (C$/t NSR cut-off grade) for the pit constrained mineral resources that define the Alexo South nickel sulphide deposit.

Figure 4. Grade-tonnage curve (C$/t NSR cut-off grade) for the out-of-pit (underground) mineral resources that define the Alexo South nickel sulphide deposit.

Figure 5. Plan map of the Alexo South MRE showing historical drill holes (red), 2021 Class 1 drill holes (blue), the pit optimized shell (grey), and Indicated (IND) and Inferred (INF) mineralized blocks.

Figure 6. Plan map of the Alexo South MRE showing historical drill holes (red), 2021 Class 1 drill holes (blue), the pit optimized shell (grey), and C$/t NSR categorized mineralized blocks.

Figure 7. Cross-section of the Alexo South MRE (looking northeast) showing historical drill holes (red), 2021 Class 1 drill holes (blue), the pit optimized shell (grey), and Indicated (IND) and Inferred (INF) mineralized blocks.

Deposit Types and Project Potential

In addition to the high-grade nickel sulphide (>1.0% Ni) potential we see at Alexo-Dundonald, immense potential exists to target and develop large tonnage, low-grade komatiite-hosted deposits such as those being developed in the Timmins area by Canada Nickel Company (Crawford Project), EV Nickel Inc. (CarLang A Deposit) and Aston Minerals Limited (Boomerang Project). The Company is currently planning a targeted diamond drilling program to outline this deposit type within the Alexo-Dundonald Project.

This two-pronged approach – develop “traditional” high-grade nickel sulphide resources and in parallel large-tonnage, low grade nickel deposits – brings together the best of both nickel deposit types which are actively and aggressively being explored for and developed within the Timmins Mining Camp.

Core Handling, Assay and QA/QC Procedures

After visually logging the NQ-size drill core from the 2021 Class 1 Nickel diamond drilling program (Alexo South Deposit), drill core was cut in half at the core logging and cutting facility with one half of the core bagged and the other half saved in the core tray and put into secure storage. The core samples were transported to either AGAT Laboratories of Mississauga, Ontario (“AGAT”) or ALS Laboratory in Timmins, Ontario (“ALS”). Samples, along with certified standards and blanks, included by the Company for quality assurance and quality control, were prepared and analyzed at AGAT and ALS. Samples were prepped using industry standard procedures and analyzed for nickel, copper, cobalt and sulphur. Analytical methods employed consisted of four-acid digest followed by sodium peroxide fusion and ICP-OES finish for multi-element analysis (including Ni, Cu, Co and S); fire-assay collection and ICP-OES finish for palladium, platinum and gold; and nickel collection fire assay and ICP-MS finish for the platinum-group elements, including rhodium. In-fill sampling of drill core, completed in early 2024, was assayed at ALS. These and future assay results may vary from time to time due to re‒analysis for quality assurance and quality control purposes.

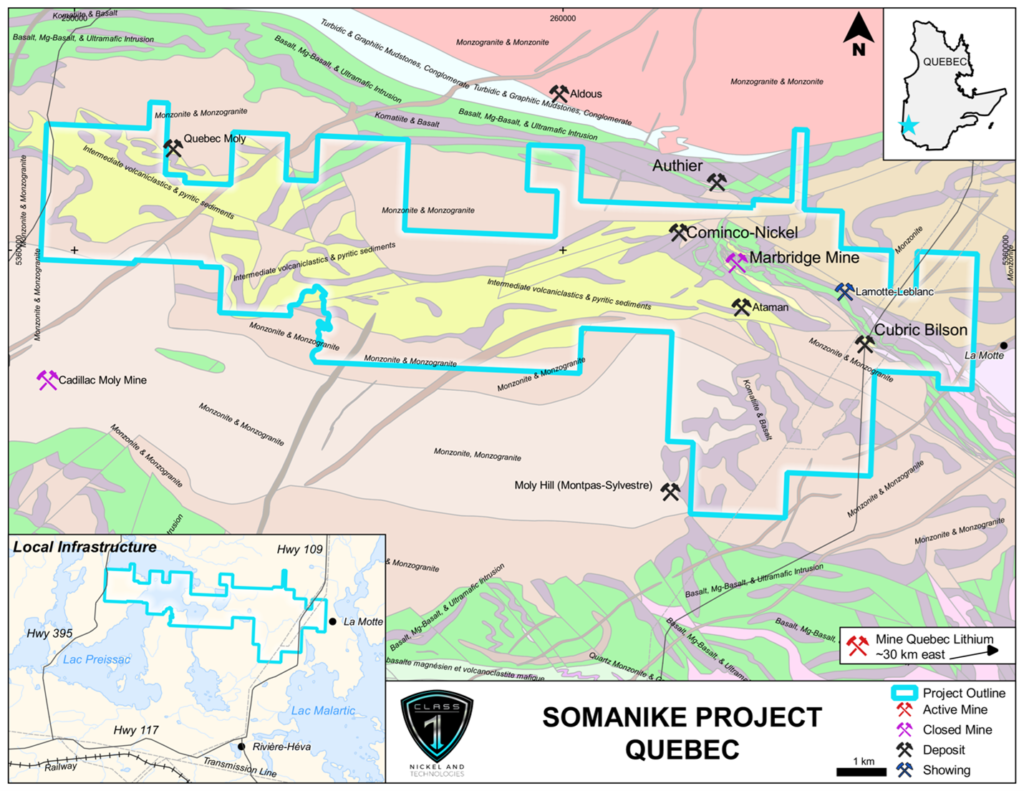

Alexo-Dundonald Nickel Project

The Alexo-Dundonald Nickel Project (“A-D Project”), is located about 45 km northeast of the City of Timmins, Ontario, covers an area of approximately 1,895 hectares (18.95 km2), and was acquired by the Company in September 2018. The A-D Project includes four foundation nickel deposits (Alexo North and South and Dundonald North and South) of which the Alexo North and Alexo South (aka Kelex) were small-scale past producers of relatively high-grade nickel (i.e., 1957; 2004-2005). The deposits are located on a near-continuous folded komatiite-ultramafic rock sequence that extends for at least 14 km within the Property and which has never been systematically explored. The four mineral resources are open at depth and along strike and could increase in size with additional drilling (see Company news release dated 18 April 2024).

Qualified Persons

The Qualified Person for the Alexo South Mineral Resource Estimate reported herein and as defined by NI 43-101, is Mr. Simon Mortimer (FAIG #4083), Principal Geoscientist at Atticus Geoscience Consulting, working with Caracle Creek International Consulting Inc. All other technical information and data in this news release has been reviewed and approved by Dr. Scott Jobin-Bevans (P.Geo., PGO #0183), a geological consultant to the Company, and a Qualified Person under the definitions established by NI 43-101.

About Class 1 Nickel

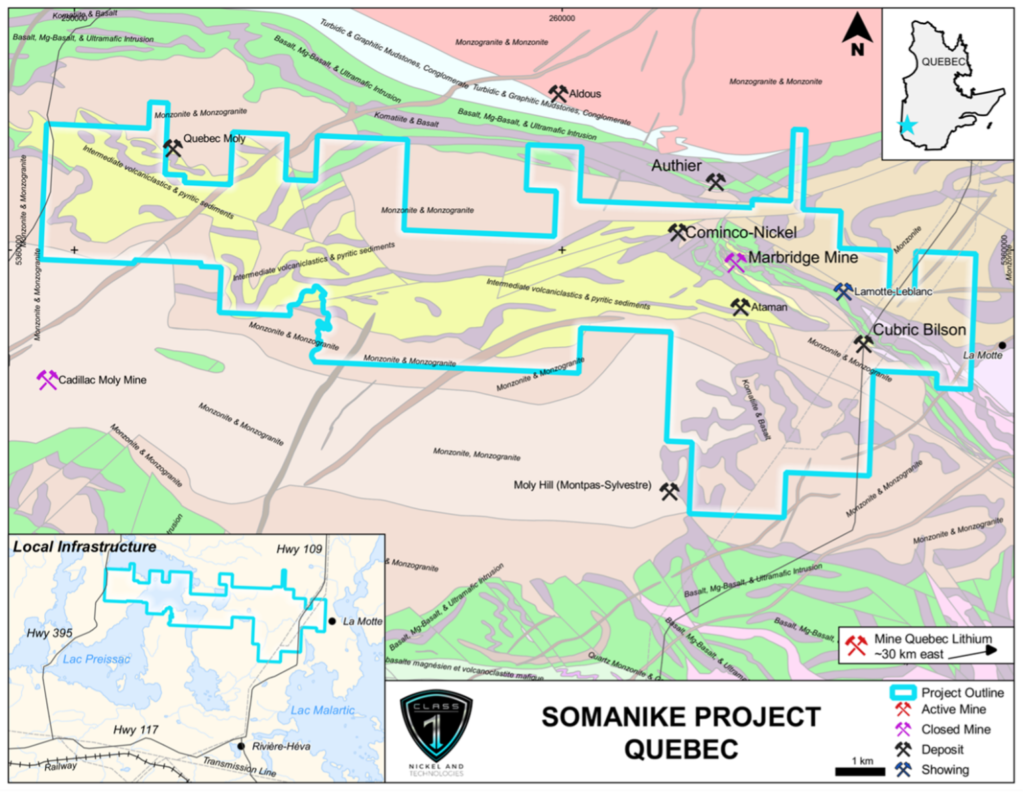

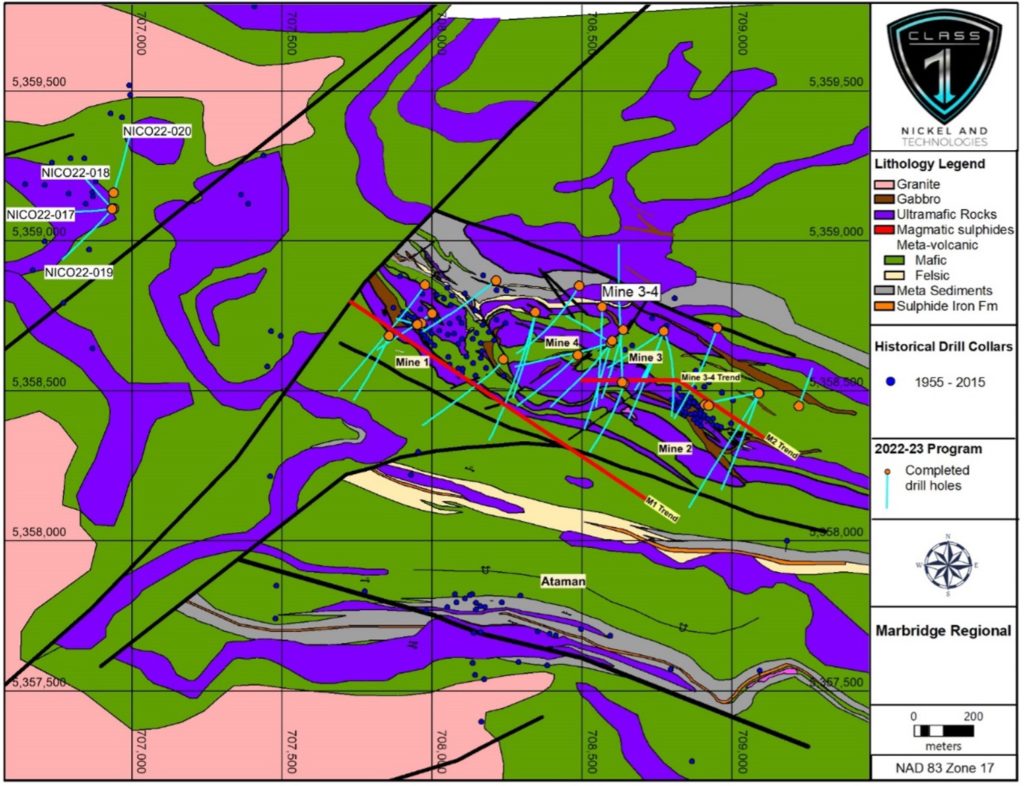

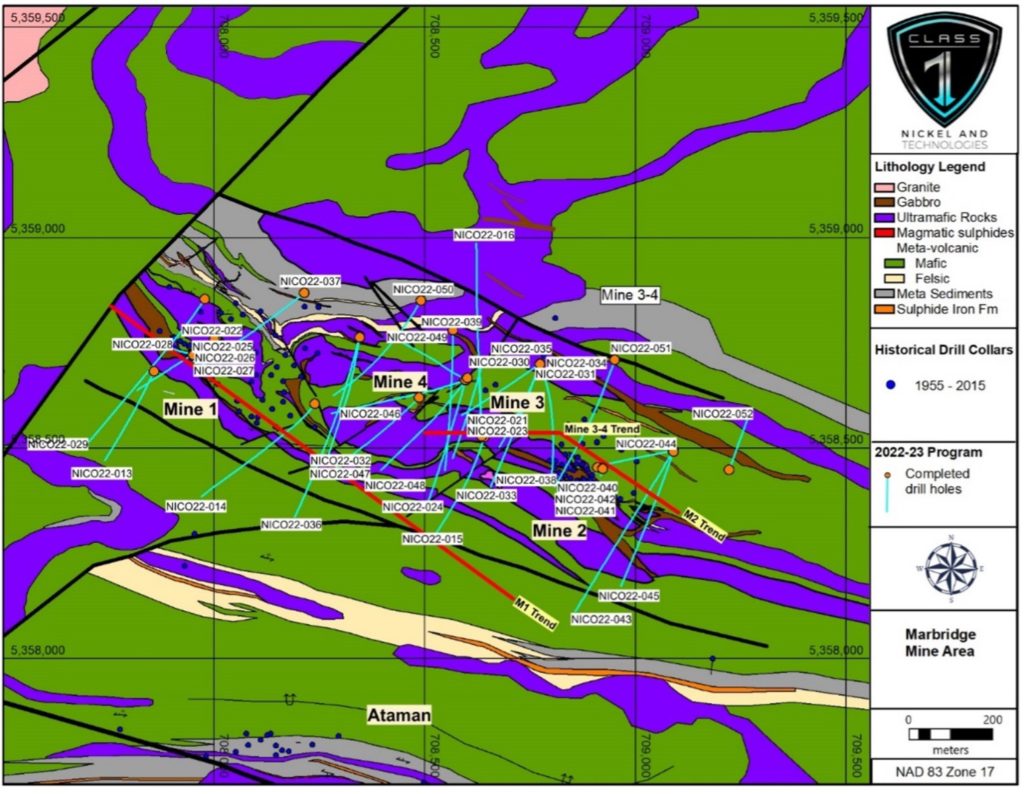

Class 1 Nickel and Technologies Limited (CSE: NICO | OTCQB: NICLF) is a Mineral Resources Company focused on the exploration and development of its 100% owned komatiite-hosted nickel sulphide projects: the Alexo-Dundonald Project, neat Timmins, Ontario (4 nickel sulphide deposits) and the Somanike Project, near Val-d’Or, Quebec (includes the historical Marbridge Ni-Cu Mine). Both projects comprise extensive property packages covering past-producing nickel mines, offering near-term production opportunity and excellent exploration upside.

Class 1’s current focus is to advance the A-D Project back into production and at the same time continue brownfield and greenfield exploration on its large property package to aggregate additional nickel resources. The A-D Project sits on a 14+ km strike-length, folded komatiite unit containing several nickel-copper-cobalt and PGE mineral resources plus numerous underexplored sulphide occurrences. Decades of successful capital expenditure and investment into the Project has resulted in the discovery and delineation of four main nickel Mineral Resources that occur along the folded komatiite unit. The A-D Project was previously mined via a direct-shipping model, and the Company will soon commence a Preliminary Economic Assessment (PEA) study to determine the best path forward.

In addition, the Company also holds 100% interest in its River Valley PGE Project located about 65 km northeast of the City of Sudbury, the world’s largest and longest operating nickel-copper-cobalt-PGE mining camp. See the Company’s 13 December 2023 new release for additional information.

For more information, please contact:

Mr. David Fitch, President & CEO

T: +61.400.631.608

E: info@class1nickel.com

For additional information please visit our website at www.class1nickel.com and our Twitter feed: @Class1Nickel.

Neither the Canadian Securities Exchange nor its regulation services provider has reviewed or accepted responsibility for the adequacy or accuracy of this press release.

This news release contains forward-looking information which is not comprised of historical facts. Forward-looking information is characterized by words such as “plan”, “expect”, “project”, “intend”, “believe”, “anticipate”, “estimate” and other similar words, or statements that certain events or conditions “may” or “will” occur. Forward-looking information involves risks, uncertainties and other factors that could cause actual events, results, and opportunities to differ materially from those expressed or implied by such forward-looking information. Factors that could cause actual results to differ materially from such forward-looking information include, but are not limited to, changes in the state of equity and debt markets, fluctuations in commodity prices, delays in obtaining required regulatory or governmental approvals, and other risks involved in the mineral exploration and development industry, including those risks set out in the Company’s management’s discussion and analysis as filed under the Company’s profile at www.sedarplus.ca. Forward-looking information in this news release is based on the opinions and assumptions of management considered reasonable as of the date hereof, including that all necessary governmental and regulatory approvals will be received as and when expected. Although the Company believes that the assumptions and factors used in preparing the forward-looking information in this news release are reasonable, undue reliance should not be placed on such information. The Company disclaims any intention or obligation to update or revise any forward-looking information, other than as required by applicable securities laws.